Комплексное высокопроизводительное промышленное оборудование для аддитивного выращивания изделий с последующей механической обработкой

Российские обрабатывающие центры комплексной аддитивной наплавки — новое поколение высокопроизводительного оборудования аддитивного производства, позволяющего изготавливать металлические окончательно обработанные детали, выращенные способом гибридной аддитивной наплавки с применением металлической проволоки, в том числе стандартной общедоступной сварочной.

Наплавка, послойное деформационное упрочнение(проковка) и фрезерная обработка осуществляется для следующих металлических материалов:

- конструкционные стали

- коррозионностойкие стали и сплавы

- жаропрочные стали и сплавы

- титановые сплавы

- алюминиевые сплавы

- магниевые сплавы

- бронзы и др.

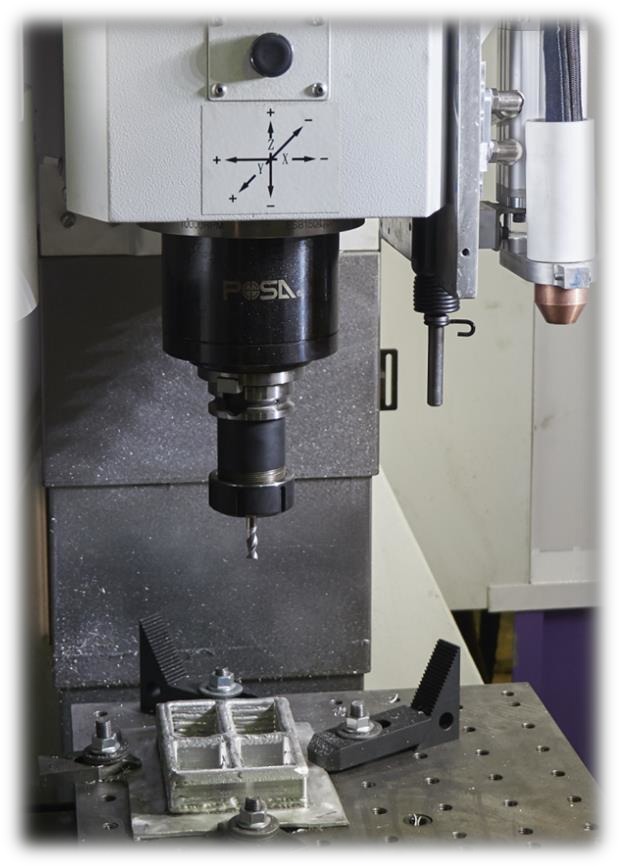

В обрабатывающих центрах комбинированы высокопроизводительная аддитивная наплавка и силовая механическая обработка. Высокая производительность, в том числе, при обработке высоколегированных сплавов достигается за счет применения монолитной чугунной станины, электродвигателей и сервоприводов с высоким крутящим моментом в широком диапазоне режимов обработки

- отсутствие необходимости производства дорогостоящей литейной и штамповой оснастки

- существенное снижение временных и материальных затрат на изготовление крупногабаритных заготовок

- значительное увеличение коэффициента использования материала до 5 и более раз

- полный цикл производства: на входе сварочная проволока и 3D-модель, на выходе обработанная деталь

- высокие механические свойства – микроструктура материала после наплавки приближается к структуре проката за счет применения уникальных плазмотронов и послойного деформационного упрочнения

- высокое качество наплавленного металла – низкая пористость

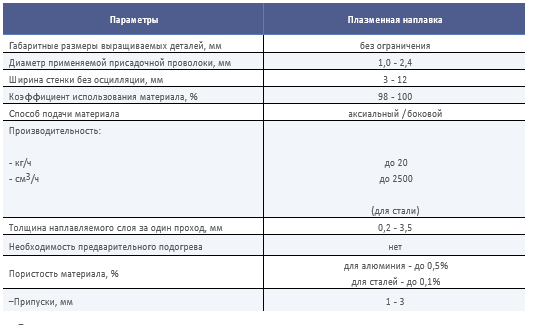

- возможность изготовления крупногабаритных деталей: на предлагаемой линейке оборудования до 3070х1200х1100 мм, по запросу заказчика габариты можно увеличить до 10 метров и более

- высокая производительность наплавки (до 20 кг/ч или 2500 см/ч на примере конструкционной стали 09Г2С)

- максимальная подача проволоки – повышенная точность производства деталей сложной конфигурации по сравнению с альтернативным оборудованием проволочной наплавки

- оборудование способно работать на обратной полярности, что приводит к явлению катодной очистки зоны наплавки

- послойное деформационное упрочнение (проковка)

- возможность применения широкого ассортимента материалов – использование проволок различного химического состава, как отечественного, так и зарубежного производства, в том числе стандартной общедоступной российской и импортной сварочной проволоки

- более низкая стоимость и доступность проволоки по сравнению с порошками для популярных аддитивных технологий

- производительность выше в 4-6 раз по сравнению селективным лазерным сплавлением (SLM)

- минимальные потери материала сокращение потерь более дорогостоящего (порошкового) материала по сравнению селективным лазерным сплавлением (SLM), прямым лазерным спеканием металлов (DLMS), технологией газопорошковой наплавки (LMD/DED)

- отсутствуют недостатки порошковых аддитивных технологий: специальные требования к обеспечению безопасности, особые требования к обеспечению защитной среды (организации подвода защитных газов, обеспечения вакуума) – обеспечивается локальной защитой и катодной очисткой зоны наплавки

- не требуется специализированной оснастки, для введения дополнительных осей возможна установка поворотных столов

- возможность высокопроизводительного изготовления окончательно обработанных деталей, в том числе из никелевых сплавов (фрезерная функция)

- относительно невысокая стоимость оборудования

- оборудование российского производства

- аддитивная проволочная наплавка

- катодная очистка зоны наплавки

- послойное деформационное упрочнение (проковка)

- локальная защита зоны наплавки

- силовая высокопроизводительная фрезерная обработка

- встроенная вентиляция и вытяжка

- устройство автоматического удаления стружки

- устройство защиты органов зрения в процессе наплавки

- ограждение зоны наплавки и механической обработки

- удобство обслуживания оборудования, используются стандартные решения для механообрабатывающего оборудования

- стандартное управление от Siemens, Fanuc

- система местного охлаждения воздухом, в том числе ионизированным

- система охлаждения СОЖ

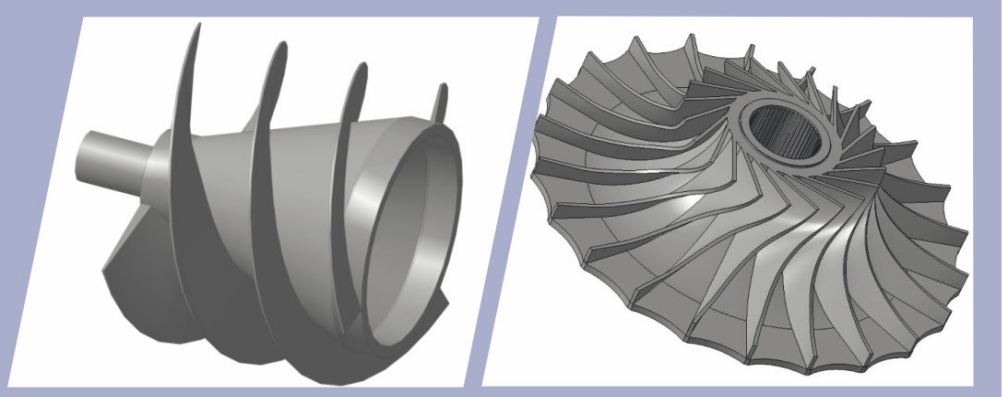

Примеры конфигураций изделий

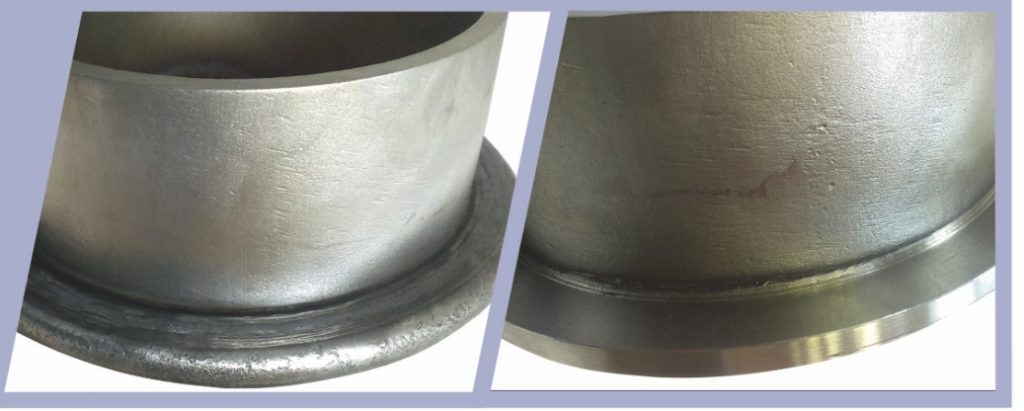

Выращивание дополнительных элементов изделий: фланец из нержавеющей стали для нефтяной и химической промышленности

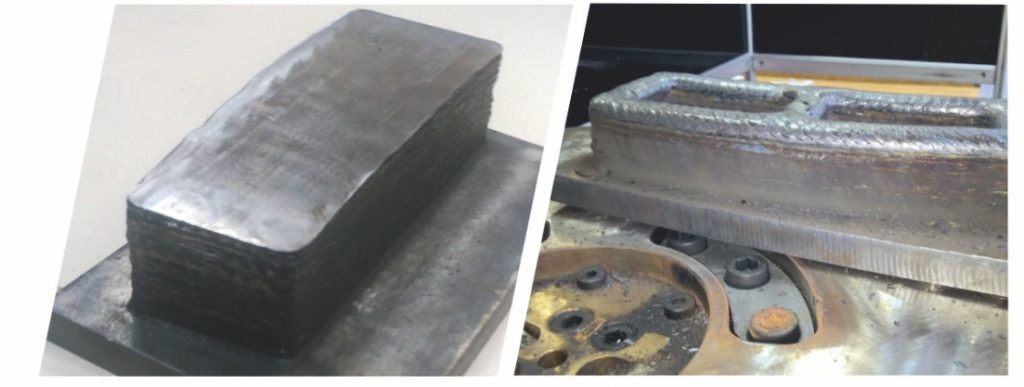

Выращивание коробочных конструкций: пуансон

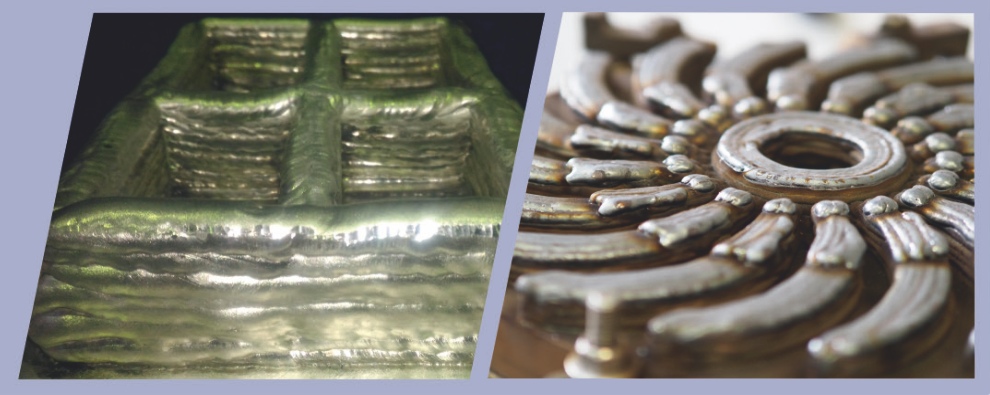

Деталь типа оребренная стенка: образцы из алюминиевых сплавов

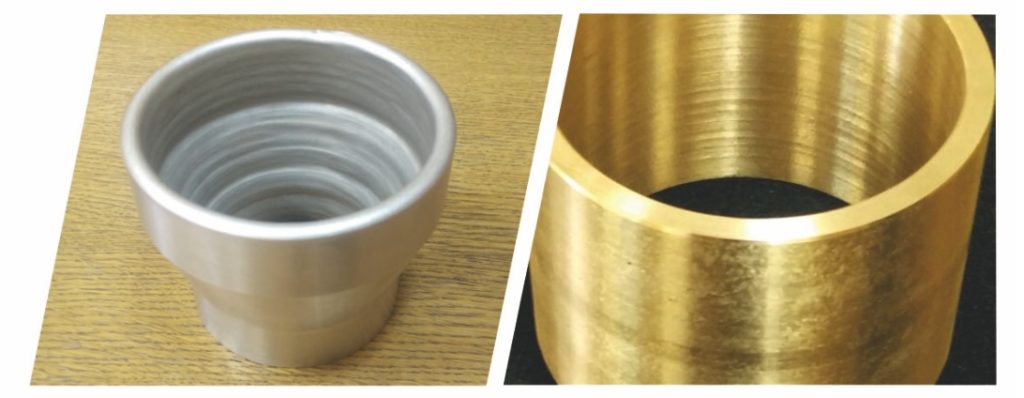

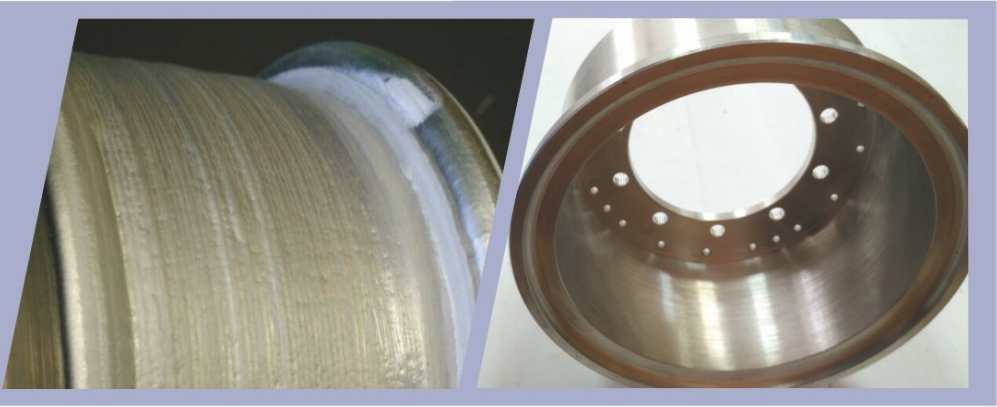

Изделия типа стакан:

тела вращения из высокопрочных алюминиевых сплавов и бронзы

Изделия типа диск

Корпусные изделия

Детали типа рабочее колесо насоса, турбины, шнек (идет отработка)